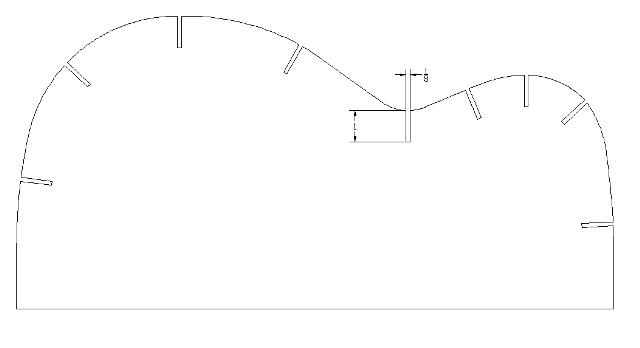

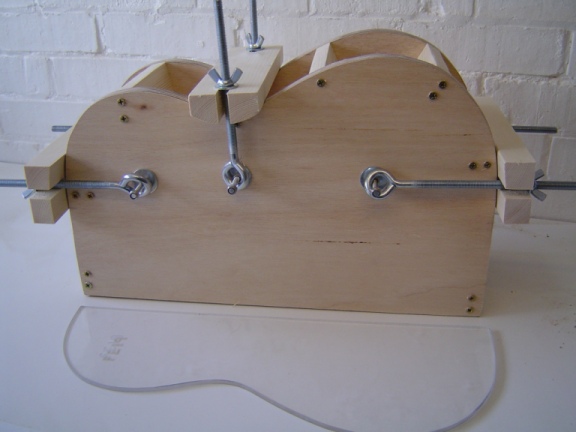

I just built a new side bending form at the weekend for a new body shape (a classical FE19) that I'm starting to put together. I have never used wooded dowels or metal rods for my bending forms as I use a blanket and the metal rods were originally used as heat sinks when using light bulbs. I always use flat stock instead.

Alignment is assured by drilling the connecting bolt holes together, I then install threaded inserts and the rods are screwed through and held with nylock nuts. The top slats are then just screwed in place and profiled to the required curves.

Just another way.

Colin

Heh, I just noticed when I put the picture up that I've left a screw out! A lot of people say I've got a screw loose!